Single Phase CNC Machine Controller

Product Details:

- Display Digital

- Frequency 50-60 Milihertz

- Product Type CNC Machine Controller

- Application Industrial

- Click to View more

Single Phase CNC Machine Controller Price And Quantity

- 18000 INR/Unit

- 1 Unit

Single Phase CNC Machine Controller Product Specifications

- Industrial

- 50-60 Milihertz

- Digital

- CNC Machine Controller

Single Phase CNC Machine Controller Trade Information

- 1 Unit Per Day

- 1 Week

- All India

Product Description

A controller created to run CNC (Computer Numerical Control) machines powered by single-phase electrical systems is referred to as a single-phase CNC machine controller. Three-phase power is frequently employed in industrial settings because of its effectiveness and capacity to handle high-power loads. Single-phase power, on the other hand, might be more practical or appropriate for smaller CNC machines in some circumstances.

Commonly found in a single-phase CNC machine controller are the following elements:

1. The control unit, which is the main part of the CNC machine controller, contains the electronics required to process control commands and carry out CNC programmes, such as a microcontroller or a PLC. It decodes the G-code commands and produces the necessary signals to regulate the motion of the machine.

2. Motor Drives: The controller communicates with the motor drives, which manage how the CNC machine's multiple axes move. These drives take the signals that the control unit sends them and turn them into the proper amount of electrical power to move the machine's motors. Whether stepper motors or servo motors are installed in the machine will determine the sort of motor drives that are employed.

3. Power Source: The controller needs a power source to function. A single-phase AC power source, often at 120 V or 240 V, depending on the particular system needs, is what a single-phase CNC machine controller is made to work with.

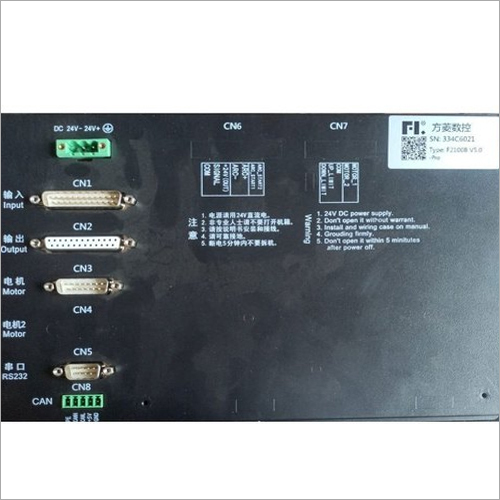

4. I/O Interfaces: The controller has input and output (I/O) interfaces for attaching accessories such limit switches, sensors, emergency stop buttons, and other auxiliary equipment. These interfaces allow the controller and the machine's external components to communicate.

5. User Interface: The CNC machine controller may have a user interface for configuring parameters, programming the machine, and keeping track of the milling operation. This interface may take the shape of a computer-based interface, a touchscreen display, or a separate control panel.

It's important to keep in mind that the availability and functionalities of single-phase CNC machine controllers can change based on the manufacturer and the particular requirements. Single-phase controllers can sometimes be built into the machine itself, but they can also be standalone devices that can be connected to suitable CNC machines.

In order to assure compatibility and acquire comprehensive information about the unique features and functionalities of the controller for your desired application, it is crucial to speak with the machine manufacturer or controller provider when thinking about a single-phase CNC machine controller.

Specification

| Material | Mild Steel |

| Country of Origin | Made in India |

| Usage/Application | CNC Machine |

| Voltage | 24 V DC |

| Phase | Single Phase |

| Operation Mode | Automatic |

| IP Rating | IP40 |

FAQ

1. What kind of CNC machine controller do I have, and how do I know?

Ans - Verify what kind of power source your system uses. While three phase controllers use three phases of power, single phase CNC machine controllers use one phase.

2. How do I link my machine to the CNC controller?

Ans - For instructions on how to connect your CNC controller to the drive or motor of your machine, go to the handbook that came with it. Normally, an encoder cable is used to link the controller to the motor.

3. What kind of language is utilised to programme single phase CNC machines?

Ans - G-code is the most widely used programming language for single phase CNC machines. Depending on the kind of machine and controller, other languages might also be employed.

4. What kinds of safety features do CNC machines have?

Ans - Depending on the kind of CNC machine and controller being used, several safety features are available. On single phase CNC machines, common safety features include limit switches, E-stop buttons, and emergency stop switches.

5. Is it possible to add new functionality to CNC machines?

Ans - Yes, many single phase CNC machines may be modified with new features like improved motors, cooling systems, and more. For further information on how to upgrade your CNC machine, speak with the maker of your controller or machine.