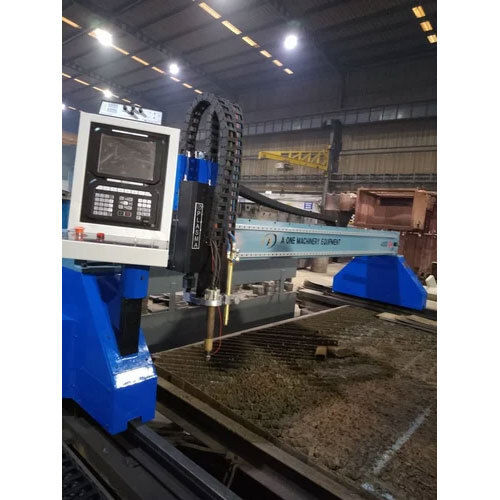

Cut 160 IGBT Semi Automatic Inverter Plasma Cutting Machine

Product Details:

- Type Inverter Plasma Cutting Machine

- Material Metal

- Automatic Grade Semi-Automatic

- Cutting Thickness 30 Millimeter (mm)

- Click to View more

Cut 160 IGBT Semi Automatic Inverter Plasma Cutting Machine Price And Quantity

- 1 Unit

- 185000 INR/Unit

Cut 160 IGBT Semi Automatic Inverter Plasma Cutting Machine Product Specifications

- Semi-Automatic

- Metal

- Inverter Plasma Cutting Machine

- 30 Millimeter (mm)

Cut 160 IGBT Semi Automatic Inverter Plasma Cutting Machine Trade Information

- 1 Unit Per Day

- 10-15 Days

- All India

Product Description

IGBT (Insulated Gate Bipolar Transistor) technology is used by one particular brand of plasma cutting equipment, the Cut 160 IGBT semi-automatic inverter plasma cutter. It has a variety of features and capabilities and is intended for manual or semi-automatic cutting operations.

The semi-automatic inverter plasma cutting machine Cut 160 IGBT has the following significant features:

1. Power and cutting capacity: The Cut 160 IGBT can produce 160 amps of cutting output. The machine's cutting capacity will vary depending on the material being cut, its thickness, and the intended cutting speed. It is frequently used to cut a variety of metals, typically up to a thickness of 25 to 30 mm, including steel, stainless steel, aluminium, and copper.

2. IGBT Technology: To provide effective and accurate control of the cutting output, IGBT technology is used in the machine's power electronics. High power conversion efficiency, enhanced power factor correction, and dependable performance are just a few of its benefits.

3. The Cut 160 IGBT uses inverter technology, making it possible for it to be small and light while still delivering stable and reliable cutting performance. Plasma cutting devices with inverter technology are renowned for their superior energy efficiency and precise cutting control.

4. Cutting Technique: The device uses the plasma cutting technique, which melts and removes the metal being cut using a high-velocity jet of an ionised gas, usually air or nitrogen. Fast cutting rates, exceptional cutting precision, and the ability to cut through a variety of conductive materials are all features of plasma cutting.

5. Control Panel and Interfaces: The Cut 160 IGBT has a control panel that enables simple operation and cutting parameter change. It might have an LCD monitor, buttons, and control knobs for adjusting the cutting current, the arc start, and other settings. For applications involving automated cutting, some models might also provide connections for connecting external devices or CNC systems.

6. The machine might use pilot arc technology, which facilitates simple arc initiation and enhanced cutting performance, particularly when working with painted or rusted surfaces. Even under difficult circumstances, pilot arc technology helps to maintain a stable cutting arc.

7. Thermal Overload Protection: The Cut 160 IGBT probably has thermal overload protection to guarantee the durability and security of the device. This safety feature protects the internal parts from overheating and potential harm from extended use or heavy loads.

8. The Cut 160 IGBT has a portable and compact form that makes it appropriate for a variety of job site applications. For ease of transport, it might have wheels or a carrying handle.

For accurate information and instructions on how to use the Cut 160 IGBT semi-automatic inverter plasma cutting machine, it is important to refer to the manufacturer's specifications, user manual, or technical literature. To guarantee correct and effective usage of the machine, these resources will provide information on specific cutting parameters, consumables, maintenance requirements, and safety precautions.

FAQ

1. What kinds of cutting are available with the Cut 160 IGBT Semi Automatic Inverter Plasma Cutting Machine?

Ans - Using both ferrous and non-ferrous metals, the Cut 160 IGBT Semi Automatic Inverter Plasma Cutting Machine provides precise, high-quality plasma cutting.

2. Can an industrial setting use the Cut 160 IGBT Semi Automatic Inverter Plasma Cutting Machine?

Ans - The Cut 160 IGBT Semi Automatic Inverter Plasma Cutting Machine is appropriate for high-quality industrial performance in manufacturing situations, the answer is yes.

3. Which types of materials can the Cut 160 IGBT Semi Automatic Inverter Plasma Cutting Machine cut through?

Ans - Stainless steel, aluminium, and steel up to a thickness of 12 mm can all be sliced through by the sliced 160 IGBT Semi Automatic Inverter Plasma Cutting Machine.

4. Are there any safety features on the Cut 160 IGBT Semi Automatic Inverter Plasma Cutting Machine?

Ans - Yes, the Cut 160 IGBT Semi Automatic Inverter Plasma Cutting Machine has a number of safety measures, including an emergency shutoff switch and an overcurrent prevention system.

5. Is there any further setup needed for the Cut 160 IGBT Semi Automatic Inverter Plasma Cutting Machine?

Ans - No, the Cut 160 IGBT Semi Automatic Inverter Plasma Cutting Machine doesn't need any maintenance beyond some general setup during the initial installation.